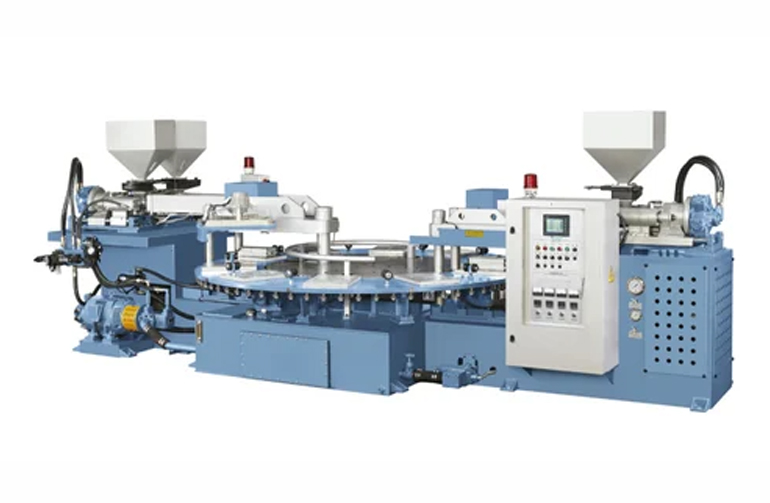

Automatic Injection Molding Machine

Injection Molding Machine

Manufacturer of a wide range of products which include double colour injection molding machine, injection molding machine, automatic injection molding machine, plastic injection molding machine, pvc injection molding machine and bucket injection molding machine.

Product Details

| Minimum Order Quantity | 1 Unit |

| Operation Mode | Automatic |

| Machine Structure | Horizontal |

| Clamping Force | 100-300 ton |

| Machine Weight | 300-350kg |

| Power Source | Electric |

| Voltage | 220V |

| Brand | Nikita |

Clamping Unit

- Rigidity of clamping system through five point double toggle system

- Less jerks & less vibration of machine thanks, to inbuilt cushion cylinder & rigid base construction.

- Multi stage mould open/close pressure & speed control. (4stage – close & 3stage – open)*

- Multi function hydraulic ejection control.*

- Set mode for mould mounting

- Toggle lubrication system by central lubrication device.

- Pre-tensioned tie bar for reliable endurance.

- Frame with catch tray and guide channels to collect surplus oil keep machine frame clean.

- Safety doors with clear Acrylic windows

Injection Unit

- Twin cylinder balanced injection system.

- Better designed ring plunger for better shot weight accuracy.

- High injection power, high rigidity of platen & fast cycling machine functions very useful for precision & stable Moulding.*

- 5 stage injection with pressure/speed/position control.*

- Plasticizing cold start prevention function.

- Automatic purging function

- Suck back function (before & after plasticization), very useful with hot runner moulds & for low viscous melts

- Inbuilt PID barrel temperature control

- Short circuit proof SSR control circuit for heater bands

Hydraulic

- High quality pump station with branded Electric Motor and Pump

- High quality vane pump with robust construction ensuring long service life & trouble free operation

- Low-noise Pump drive system

- Tube type oil cooler (Highly efficient & easy maintenance)

- Provision of lids to clean oil tank

- Efficient piping by using max. no. of hoses thus achieved zero oil leakage.

Control System

- New generation highly reliable controller.

- Operator Friendly Screens with direct access

- System can be flexibly expanded with modules

- Mould date storage

- Running function display by LED on function keys & status message on MMI.

- Machine cycle timing details in a single screen

- Hourly & monthly production monitoring system with cumulative production counter.

- Control panel temperature display and Interlock for overheat.

- Ethernet interface port

- Membrane keys to operate machine axes and application options.

Our Contacts

-

Maanila Plastic Industries

No. 2, Shramjivi Udyog, Vasahat, Behind Union Industrial Estate, Near Ramdev Mandir, Shastri Nagar, Ahmedabad - 380023, Gujarat, India. -

+(91)-9974092673

+(91)-9426071673

- info@maanilaplasticindustries.com